ABK

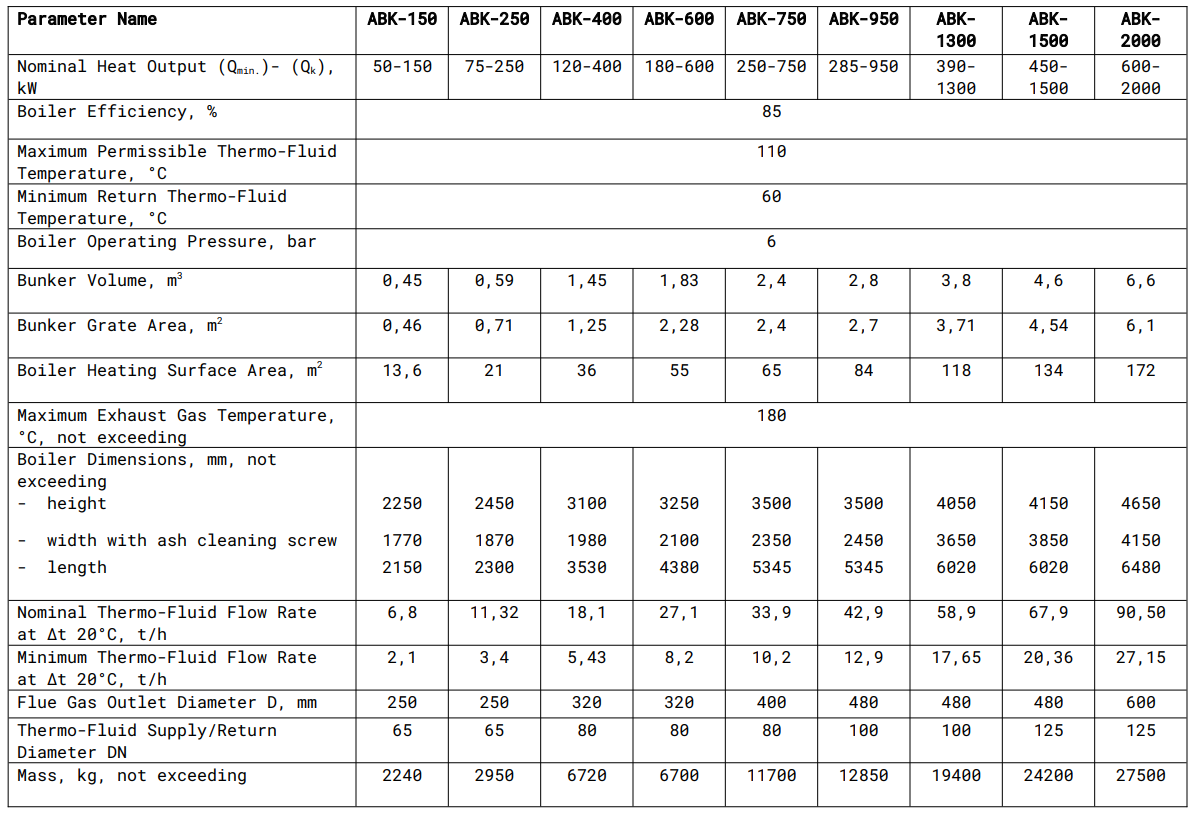

Specifications

Description

ABK type boilers with a movable grate are designed to burn fuel with moisture content up to 43%. These boilers are manufactured with a power range from 150 kW to 2000 kW. ABK type boilers come equipped with a single ash removal arch. Wide selection of fuel types: wood chips, sawdust, pellets, and other dry fuels. High efficiency coefficient up to 85%. Control range of ABK model boiler is 30%-100%. Boiler specification and features:

- Movable grate installed in the combustion chamber.

- Primary air supplied to separate combustion zones (2 or 3 zones).

- Secondary air supply to the bunker.

- Integrated ash multicyclone.

- Automatic ash removal from under the grate.

- Automatic ash removal from the bunker.

- Pneumatic heat exchanger cleaning device for each heat exchanger tube.

- Screw or hydraulic fuel feed to the bunker.

- Protection against bunker overheating.

- Protection against boiler overheating.

- Primary and secondary air heated by the combustion products. Boiler automation control options:

- Operation of fuel storage and conveyors.

- Fuel dosing into the bunker.

- Hydraulic system for the grate.

- Primary and secondary air fans.

- Ash removal from under the grate.

- Ash removal from the bunker.

- Heat exchanger purge algorithm.

- Maintaining the assigned traction in the bunker.

- Flue gas recirculation (optional).

- Combustion process control according to the “λ” zone.

- Control of the boiler recirculation pump or three-way valve according to the assigned temperature.

- Sending emergency messages via GSM.

- Boiler control remotely (via the internet).